Prototyping & Inventing

Reynolds carries a full line of silicone rubbers that will help with your development process by reproducing perfect detail from any original model. We also have a complete line of liquid plastics that offer different physical and performance properties for casting into your silicone mold to make copies of that original. Our prototyping client list includes NASA, SONY, General Motors, The US Army, Boeing, Disney and thousands of other industry leaders around the world.

![[Image of materials being used in the Prototyping & Inventing application.]](http://www.reynoldsam.com/processwire/site/assets/files/1538/appproto01_1.png)

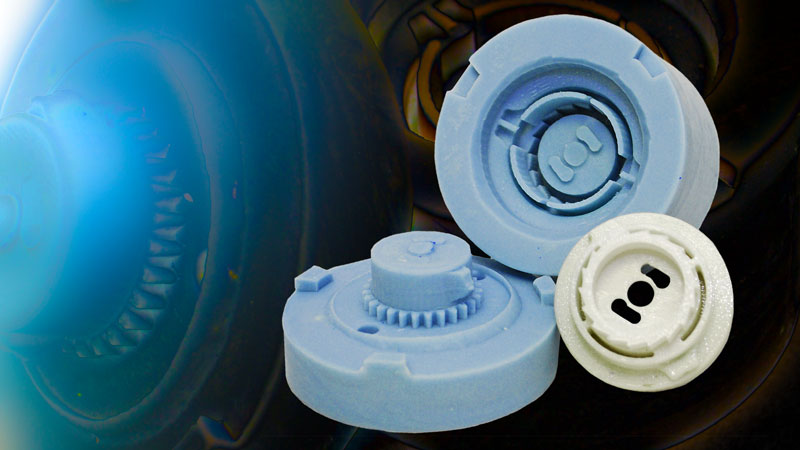

![[Image of materials being used in the Prototyping & Inventing application.]](http://www.reynoldsam.com/processwire/site/assets/files/1538/appproto02_1.png)

Popular Products

Mold Star 15, 16 & 30

1A:1B mix by volume, low viscosity platinum liquid silicone rubbers. No vacuum degassing needed.

FOAM-iT!

Two-component water blown rigid liquid foams that are versatile and easy to use.

Smooth-Sil Series

Versatile room temperature curing platinum silicones available in many different hardnesses.

TASK 2 & 3

Low viscosity, high performance white casting resins

TASK 21

Performance urethane casting resin with high ABS-type compressive and flexural strength

Videos

Making a Platinum Silicone Mold of an SLA Printed UV-Cure Model

How To Make Ear Savers Using Mold Star™ 20T Silicone and Smooth-Cast™ 65D Resin

How To Make a Reusable DIY Silicone Respirator Using Mold Star 20T Silicone Rubber

How to make a DIY Respirator Using Ecoflex™ 00-35 Silicone and TASK™ 8 Urethane Resin

How To Make a DIY Face Shield Using Mold Star™ 16 Silicone and Smooth-Cast™ 65D Liquid Plastic

How To Make a Custom Steering Wheel: Part 1, Silicone Moldmaking

How To Make a Custom Steering Wheel: Part 2, Resin Casting

Prototyping an Impact-Resistant Rectangular Sifting Mat

Prototyping a Durable Conveyor Belt Cleaner

How To Make a Silicone Mold of a Prototype Part Using Smooth-Sil® 960 Silicone

How to Make a Silicone Mold of 3D Printed PLA featuring Mold Star 20T Silicone

Strengthening a 3D Powder Print with XTC-3D Epoxy Resin Coating

Images

Smooth-Sil® 950 used to make prototype components.

Mold Star® 15 two piece mold used for prototyping.

Mold Star® 16 silicone mold rubber used for prototyping plastic handle cast with SmoothCast® ONYX®.

TASK® 2 urethane plastic used to create prototype oversize remote control.

TASK® 21 urethane plastic resin prototype from a Mold Star® 15 silicone rubber mold.

TASK® 2 urethane plastic cast of a jet boat intake from a Mold Star® 30 silicone rubber mold.

Smooth-Sil® 950 was Dead Dog Design's choice of mold rubber which yielded over 100 castings of this football tee prototype in less than 30 days.

![[Return to Homepage]](/assets/imgs/RAMlogo.png)