Rotational casting (also known as slush casting) refers to pouring a small amount of resin or other material into a rubber mold cavity and rotating the mold until the resin cures against the mold surface. Usually, a minimum of 3 to 4 successive pours are made into the mold, and layers are built up to ultimately create a casting that looks solid but is hollow.

Advantages of Rotational Casting

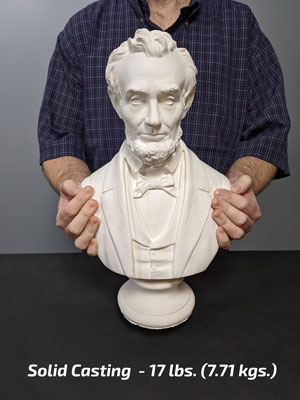

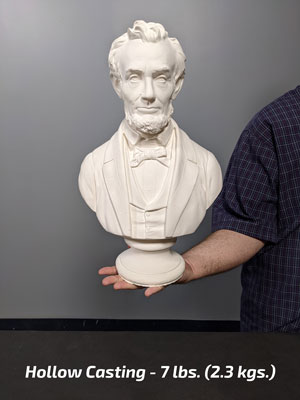

Finished castings look perfectly solid and 3 dimensional but weigh much less compared to a casting that was poured solid. Because you use much less resin to create the hollow casting, your cost per casting is considerably less. Some larger pieces can be challenging to cast solid with resin because of the weight and potential for a high amount of heat generated from the curing process leading to shrinkage and distortion.

|

|

Disadvantages of Rotational Casting

The time and labor associated with making rotational castings is considerably more compared to pouring solid castings. Some larger or complex molds may be challenging to slush cast, especially by hand (see "Machine Rotational Casting" section below).

How to Rotationally Cast a Mold

- Fill the mold cavity with enough resin to build up a single layer.

- Rotate the mold at a constant rate and as close to a 360 degree rotation as you can get so that the resin coats the inside of entire mold cavity.

- Once the resin gels (stops flowing and becomes tacky) repeat Steps 1 & 2 until desired thickness is achieved.

Note: Determining the correct amount of resin may take a few attempts before you get a finished casting that you like.

Hand Rotational Casting

Some molds lend themselves to be rotationally cast by hand. The limitation is size. A mold that is 6" × 6" × 6" (15 cm × 15 cm × 15 cm) may be physically manageable. A mold that measures 3' × 3' × 3' (0.9 m × 0.9 m × 0.9 m) would be heavy and very hard to rotationally cast by hand.

Watch how to hand rotationally cast in the video above

Machine Rotational Casting

Rotational casting machines are efficient and ideal for creating uniform castings every time and are ideal for larger molds that would be harder to slush by hand. Using a roto machine, you can be successful roto casting almost any resin including “snap cure” resins. Machines can be purchased commercially. There are also online instructions for building your own. We have heard mixed results about these types of machines. Some good, some terrible.

Watch how to rotationally cast using a rotocasting machine in the video above

Finishing the Job

Hollow castings of some materials, like gypsum, will break easily if dropped. For gypsum or polymer modified gypsums like Matrix NEO or Matrix Dryve, layering in a mixture of material and chopped glass fiber will reinforce all layers and make castings more impact resistant.

For resins, once you have enough layers built up to form your hollow casting, “backfilling” the mold cavity with rigid or flexible expanding foam (FOAM-iT! rigid foams or FlexFoam-iT! Flexible foams) is an economical way to make your castings far more impact resistant.

Selecting the Right Material for Rotational Casting

A variety of materials can be used for rotational casting including some urethane resins, gypsum plasters, polymer modified gypsums and more. To determine a suitable material, you need to look at the "cure profile".

Some resins "snap cure" (e.g., Smooth-Cast 300), meaning that the resin goes from liquid to solid almost instantly at the end of the pot life. If you try to rotationally cast a resin with this type of cure profile, you can end up with uneven or incomplete coverage and an inconsistent wall thickness.

Other materials have a "gradual cure profile" instead of a snap cure. These types of materials lend themselves to building even, consistent layers on the inside of the mold cavity.

![[Return to Homepage]](/assets/imgs/RAMlogo.png)